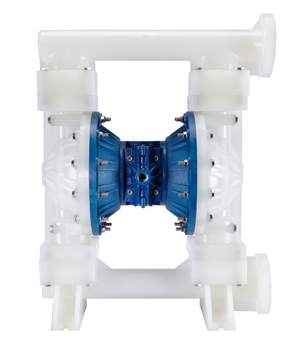

Understanding Compressed Air and Diaphragm Pumps

Q: We recently installed AODD pumps and I don’t think our chief engineer has the compressed air setup correctly. What are some basic recommendations to make sure we get the most out of our pumps?

A: It’s very common for people to invest a lot of time researching the pump brands, sizing the pumps and finding the right supplier, but then pay less attention to the compressed air. This is the A in the AODD – for air – so it’s a very important part of the system. For the pump to work at its peak level of efficiency, the compressed air has to be setup the right way. Here are a few thoughts to get you started in the right direction:

Check the air compressor size to be sure it’s the right size for the pump. PSI at the pump discharge must be equal or greater at the inlet – but PSI isn’t enough. Check the air compressor’s SCFM – Standard Cubic Feet per Minute. This measures how much air it can deliver to the pump. Every pump manufacturer states the recommended SCFM for each pump. Too low and the pump will never deliver the performance  anticipated.

anticipated.

Make sure the pump isn’t running at max air pressure. This is like driving a family car at 120 mph. It would be nice to get to soccer and karate faster but puts too much wear and tear on the engine. AODD pumps excel when run at 80-90 psi as the max air pressure.

Check the air going to the pump. Since it needs to be clean and free of contaminants, consider installing an air filter, along with a regulator and needle valve to control air volume and speed to the pump. If the pump is set at the end of the air compressor line then condensation may become an issue and adding an air dryer is recommended. Of course, check for leaks in the piping and avoid PVC since it gets brittle over time.

Keep the temperature of the compressor the same all year. The compressor room needs to be cool (<100 degree F) and well ventilated to prevent overheating but freezing temperatures cannot be allowed.

The condition and settings of the compressed air line affect how quickly the wear parts in the pump actually wear. All of these parts come with a finite but extendable service life so preventive maintenance on these parts pays major dividends. Keep these spare parts on hand, just in case: diaphragms, valve balls, valve seats, glyd rings, pilot sleeves and others, depending on the pump.

See spare parts kits for Wilden here. For other brands, call 203.740.1877.